Industrial machinery

Quality assurance and quality control are important parts of the industrial machinery industry, and Global Wits Consultancy Services has been providing these services.

The Industrial machinery industry is constantly evolving and it’s important to have the right equipment and quality to meet market expectations. Global Wits Consultancy Services assists buyers and suppliers with a wide range of quality assurance and quality control services designed for the needs of the industrial machinery industry. We are dedicated to ensuring quality across the Industrial machinery industry as well as creating a trustful environment between buyers and sellers.

Industrial machinery firms cherish honesty, transparency, and control in their relationships with suppliers. Depending on their experience, they may partner closely with a manufacturer for an all-in-one solution. Global Wits Consultancy Services will also improve this relationship by supplying them with a high-quality supplier management suite that covers every step of the production process. When it comes to quality assurance services, Global Wits Consultancy Services is a trusted partner for success. Our team help solves non-conformities during the production process and ensures compliance with quality management standards. Whether companies are looking to improve their factory performance or control product quality, our expertise and reliability will be invaluable to them.

Our Solutions

For over four decades, Global Wits Consultancy Services has helped businesses and customers create high-quality industrial machinery. We have tailored our quality assurance and quality control solutions to cover each major industrial machinery industry sector, including:

- Packaging Machinery

- Food Processing Equipment

- Plastics Processing Machinery

- Metal Forming Machine Tools

- Woodworking Machines

- Printing Machinery

- Semiconductor Machinery

- Chemical Processing Machinery

- Glass Making Machinery

- Tannery Machinery

- Textile Making Machinery

- Others

Quality Assurance & Quality Control for Industrial Machinery

Manufacturing Audits and Advisory

Take advantage of our end-to-end comprehensive approach to improve your supply chain performance.

- Manufacturing Process Audits

- Process Improvement

- Production Capacity Analysis (Run & Rate)

- Quality Investigation (root cause investigation of a defective product)

- Root Cause Analysis

- Corrective Action Follow-Up

- Process Failure Mode Effects Analysis (PFMEA)

- Continuous Improvement

Manufacturing Process Audit

Global Wits Consultancy Services is a global quality assurance company that offers manufacturing process audit solutions across five continents. We help qualify suppliers, validate production line processes, and investigate the root causes of defects.

In our experience, the quality performance of a good factory varies by production lines due to multiple factors such as people, equipment, materials, methods, production environment, and a plethora of other factors.

Global Wits Consultancy Services’s Manufacturing Process Audit focuses on assessing the specific production line that is or will be producing your product. The assessment will assess the quality practice of a product from incoming material, through to every single stage of the production process, including material handling, in-process quality control activities, outgoing QA, and warehousing.

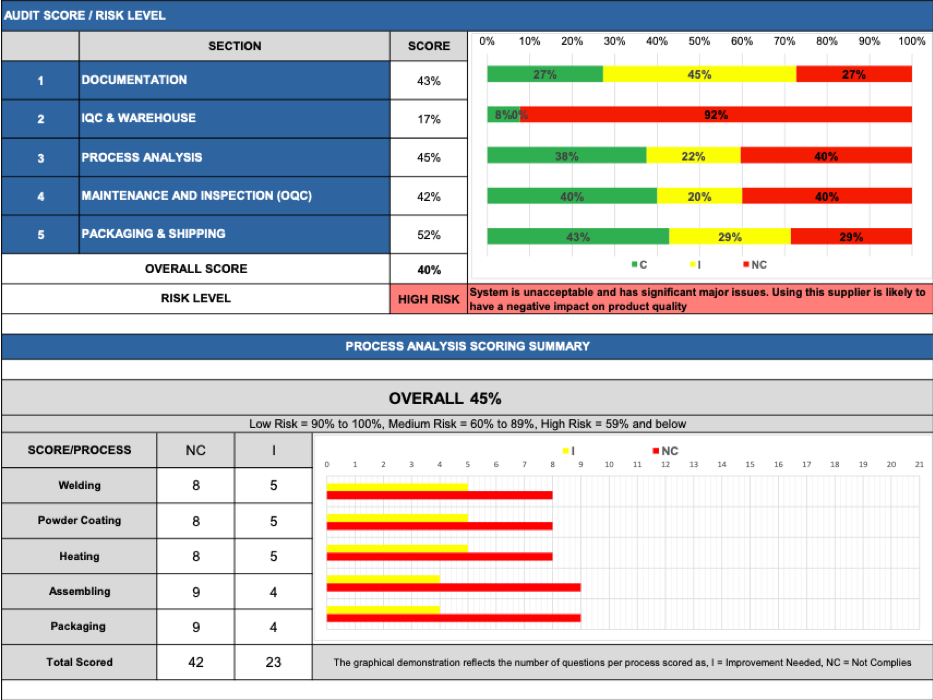

The outcome of the Manufacturing Process Audit is a thorough manufacturing audit report which includes a risk-based process control analysis of the factory. The report consists of Global Wits Consultancy Services’s risk recommendations, on-site observations, performance scores, and high-resolution photos. The report will be used by supply chain and quality professionals to make better-informed decisions about the finer details of their supplier for factory performance.

When is a Manufacturing Process Audit Required?

Our clients often choose our Manufacturing Process Audit service for four reasons:

1. Supplier Qualification

Most companies have their own set of supplier onboarding processes and criteria to prequalify and manage their suppliers. In tandem with the internal approach, many clients use our Production Process Audit as part of the onboarding assessment. This assessment provides a deeper understanding of a specific production or assembly line of their product and another set of data points to consider before placing a purchase order.

This is especially useful for large orders of technical parts or assembly-intensive products where identifying and subsequently mitigating specific production risks is paramount.

2. Preproduction validation

Before entering mass production, conducting a thorough manufacturing process audit is paramount. By scrutinizing each step of the production process, manufacturers can identify potential flaws, streamline operations, and prevent costly deviations from standards. Production Process audits also play a pivotal role in upholding regulatory compliance, ensuring that products meet industry guidelines.

This meticulous process evaluation ensures that production processes align with defined standards, preventing defects, optimizing operations, and mitigating risks. By identifying these problems and risks before mass production, buyers can prevent defects from being produced in the hundreds of thousands, thereby reducing the cost of risk and poor quality.

3. Root Cause Investigation

Suppliers tend to perform well and produce according to specifications in the early days of the buyer-factory relationship. Over time, key personnel may change, operators come and go, tools and equipment wear out, processes drift and, as a result, the quality of the product deteriorates. This may manifest itself in any number of issues including delayed shipping, unanswered emails or complaints, receipt of defective products, and even field failures.

At the first sign of any field failure or receipt of a defective product, our client triggers an 8D and engages Global Wits Consultancy Services to investigate the root cause of the quality defect. Global Wits Consultancy Services will send our auditors on-site to analyze the problem through a thorough Manufacturing Process Audit. This risk-based analysis of factory process controls identifies the production bottlenecks, sources of defects, and activities that are poorly executed or lack standard quality control. We then report back to the client with the results and recommended actions, including dates for a Global Wits Consultancy Services follow-up visit.

4. Continuous Improvement & Sustainable Performance

Efficiency gains are another noteworthy benefit. Buyers and manufacturers can implement improvements that enhance resource allocation and reduce production costs by pinpointing inefficiencies and bottlenecks through manufacturing process audits.

Moreover, a manufacturing process audit fosters continuous improvement. Insights gleaned from audits guide the adoption of best practices, innovative technologies, and optimized methodologies.

Incorporating audits within preproduction activities leads to an all-encompassing approach to quality control, bolstering product excellence and customer satisfaction. Ultimately, the manufacturing process audit serves as an invaluable tool for manufacturers to uphold standards, minimize risks, and elevate their production processes to new heights of success.

Manufacturing Process Audit Assessment Criteria and Report

We understand that every product and component has its own specific production process and corresponding criteria, and we treat each client challenge as unique. That said, Global Wits Consultancy Services has developed a unique manufacturing process audit framework and approach that can be applied across most industries, production, and product types.

Global Wits Consultancy Services’s manufacturing auditors and experts will work with your team to tailor our manufacturing audit checklist to your specific production line and dive deep into your quality problems.

Our Manufacturing process audit checklist:

- Technical Documentation

- Incoming Quality Control (IQC) & Warehousing

- Process Analysis (IPQC)

- Process Input

- Process Management

- Personnel Resources

- Material Resources

- Process Efficiency

- Process output & results

- Maintenance and Inspections (OQC)

- Packaging Shipping

Global Wits Consultancy Services assigns process auditors and quality engineers with relevant experience in the industry, product category, and processes to perform the on-site Production Process Audit assessment.

The resulting report gives our client a snapshot of the risk profile of their production line and helps pinpoint areas with the highest room for improvements.

Supplier and Factory audits

Global Wits Consultancy Services provides a broad range of factory audit solutions to the industrial machinery industry:

- Supplier Verification

- Supplier Quality Audits

- ISO 9001 Quality Management System Audits

- ISO 14001 Environmental Management System Audits

- ISO 45001 Management Systems of Occupational Health and Safety Audits

- Social Compliance Audits

- Supply Chain Security Audits

- Combined Audits

Factory and supplier audits are systematic evaluations conducted to assess manufacturers’ or suppliers’ quality management systems, operational capabilities, and compliance levels.

Global Wits Consultancy Services offers tailored factory and supplier audit services years of expertise. As a trusted partner, Global Wits Consultancy Services supports businesses that need to:

- Verify the reliability and capabilities of new suppliers

- Ensure supplier compliance with standards and industry best practices

- Prepare a factory for a certification audit or maintain existing certification

- Meet client compliance requirements

- Identify non-compliance issues and implement corrective and preventive actions

- Improve factory manufacturing performance to achieve quality excellence

Industrial Machinery Inspection Services

Our quality control inspections for industrial machinery include:

- First-Article Inspections (FAI) are performed prior to mass production. Product properties are measured and compared with specifications to verify quality matches.

- In-Process Inspections (IPI) ensure that the processes and techniques used to manufacture machinery are followed.

- Pre-Shipment Inspections (PSI) vverify the conformity of machinery to specifications before shipping. Inspectors evaluate workmanship, functionality, packaging, labeling, and other criteria as required.

- Container Loading Supervision (CLS) ensures that proper methods are employed during product loading, and counts are verified on-site.

- Sorting services are used to inspect production and detect quality issues or perform rework operations.

- Factory Acceptance Test (FAT)

- Welding Inspections

For third-party quality inspection services, Global Wits Consultancy Services recommends the International Inspection Standard ANSI Z.1.4-2003 (ANSI Sampling Table) to determine the number of units that will be randomly selected for evaluation.

Samples are checked against a detailed inspection plan for appearance, applicable functionality, packaging integrity, workmanship, and the client’s specific requirements. Discovered defects are classified as major, minor, or critical depending on the inspection plan. We have no concern to follow our customer’s QC standards, procedures, and documentation.

Global Wits Consultancy Services’s quality control inspection services apply to all industries and are tailored to the requirements of each project. From 100% to AQL-based inspections, our solutions cover the entire spectrum of quality inspections and include First Article Inspections (FAI), In-Process Inspections (DUPRO), Pre-Shipment Inspections (PSI), and Container Loading Supervision (CLS).

Our product inspection reports and results with digital photos are delivered to our clients within 24 hours of the service through our secure online client center so that product shipments can be quickly authorized.

Advantages of QC Inspections

- Avoid Costly Product Defect and Shipment Delays: Quality control (QC) inspections minimize the number of costly defects by detecting non-conformances throughout the production cycle before it is too late.

- Identify or Explore Corrective Actions: Product quality inspection services help companies determine the overall quality of their order, and determine the need to issue corrective actions before any products leave the factory

- Protect Brand and Reputation: Sub-standard products result in customer complaints and damage brand reputation. Third-party product quality inspections help ensure consistent customer satisfaction and maintain brand integrity.

Companies must provide quality products that are safe for the end users and, at the same time, be quick to market, build a strong brand, and maintain long-term growth. In times of complex international supply chains, many of the world’s top organizations rely on Global Wits Consultancy Services’s third-party quality inspection services for ensuring product quality and reducing sourcing risks around the globe.

Our Range of Third-Party Quality Inspection Services

Quality and purchasing departments demand that their suppliers meet high product quality specifications. As a global third-party inspection company, Global Wits Consultancy Services offers quality solutions throughout the entire production cycle. This allows our customers to identify defects, ensure product quality, and reduce the cost of poor quality.

Global Wits Consultancy Services’s local quality control inspectors and quality consultants work in partnership with our clients and are deployed accordingly to the project requirements and their specialization. Our team includes specialized quality inspectors in textile, footwear, furniture, medical devices, electrical, electronics, automotive, mechatronics, mechanical, welding, coating, painting, piping, and more.

Our range of quality control inspection services include:

- First-Article Inspections (FAI): As a global third-party inspection company, Global Wits Consultancy Services inspects first-article samples prior to volume production. This inspection in quality verifies that product specifications are being met and avoids unnecessary reengineering work later.

- In-Process Inspections (IPI/DUPRO): An in-process QC inspection, also called: During Production inspection, evaluates random samples from production lots when the process is circa 20-30% complete. This confirms the product quality and allows any necessary changes to be addressed early on, reducing rework time and costs.

- Pre-Shipment Inspections (PSI): During a pre-shipment inspection, our engineers verify that finished goods conform to the most stringent specifications. A pre-shipment inspection (PSI) generally occurs when production is 100% complete and packaging is 80% complete. For example, if an automotive product or auto part inspection is required, we would request the specifications and golden samples in advance. These would then be used to ascertain the quality of the products produced at the supplier. Pre-shipment inspections are also known as pre-dispatch inspections.

- Container Loading Supervision (CLS): Global Wits Consultancy Services ensures that proper methods are employed during product loading, and we verify counts on-site. Products conformance to international standards will also be verified.

Supplier Management

Global Wits Consultancy Services’s Supplier Management Solutions enhance compliance and performance of the entire supplier portfolio by:

- Performing an on-site risk assessment

- Establishing a corrective action plan

- Verifying corrective action implementation through detailed follow-up activities

- Scheduling subsequent annual visits based on supplier risk level

- Providing a supplier portfolio dashboard and performance analysis

Our supplier management team will create a customized checklist that meets exacting requirements. The supplier management service is particularly suitable for small QA teams with a large supplier base across the globe. Global Wits Consultancy Services assists these teams to investigate and resolve compliance and quality issues in a timely and cost-effective manner.

Buyers, procurement managers and quality managers play a vital role in ensuring supplier quality. This encompasses proactive performance monitoring to identify and mitigate costly risks and errors.

Global Wits Consultancy Services

offers a robust set of services to ensure supplier quality, which we call the Supplier Management Toolkit. The toolkit is designed to help anyone managing supplier quality to navigate the challenges of meeting supplier compliance and quality standards and delivering quality products.

Our stage-based Sourcing Lifecycle applies to virtually any product or component, guiding you from new product development to outgoing QC and shipment.

Below, we outline each stage of the sourcing journey and highlight the common risks and challenges faced in supplier management, helping you safeguard your supply chain and uphold your brand’s reputation.

Development & Planning;

New product development lays the foundation for strategic sourcing. Prototyping is crucial to validate that the supplier understands the client’s requirements.

Global Wits Consultancy Services inspections validate the new parts while our supplier development services align quality expectations with suppliers and strengthen their ability to meet quality requirements and reduce time to market.

Global Wits Consultancy Services’s Quality Solutions:

First Article Inspection (FAI)

Supplier Development Services

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Poor communication of technical details between buyers and factories

Misalignment of product specifications and critical design requirements among buyers, suppliers, and factory production teams

Inadequate consideration of advanced product quality planning

Challenges when transitioning from prototype suppliers to mass-manufacturing suppliers

Misalignment on design and engineering revisions

Once the component specifications are defined, the procurement department identifies a list of suitable suppliers that can potentially meet their capability, cost, capacity, and quality requirements.

Global Wits Consultancy Services offers a range of supplier due diligence and supplier evaluation support. Our experts visit suppliers to assess their capabilities, mitigate the risk of scams, overpromises, and miscommunication, and validate their credentials, trustworthiness, and financial stability.

Global Wits Consultancy Services’s Quality Solutions:

Supplier Quality Audits

QHSE Audits

ESG Audits

Onsite Supplier Verification

Financial Credit Check

Supplier Risks & Challenges:

Lack of experience and due diligence in new supplier region

Communication challenges

Concern about supplier scams

Low confidence supplier’s trustworthiness

Concerns over supplier’s financial viability

A world-class organization usually has a comprehensive supplier qualification program to identify and mitigate the risks associated with quality, safety, on-time delivery, cost, and compliance.

Global Wits Consultancy Services establishes a global audit program to systematically onboard new suppliers, categorize their risk levels, and establish a reaction plan based on the supplier’s performance on quality systems, environmental management, and social and ethical compliance.

Global Wits Consultancy Services’s Quality Solutions:

Global Supplier Audit Programs

Supplier Quality Audit for Potential Suppliers

Quality Management System Audit

Social & Ethical Audits

Supply Chain Security Audit

Environmental Audit

Supplier Risks & Challenges:

Suppliers are not as capable as they initially claimed

Supplier lacks effective and systematic quality assurance practice

Supplier is ISO 9001 certified, but the underlying principles are not implemented in practice

Mass production quality does not match prototype quality

Buyers want to sell to big retailers, but their suppliers do not yet comply with the retailer’s supplier code of conduct

Supplier violation on labor law, ethical and environmental compliances

Goods held in customs due to supply chain security malpractice

Before commencing volume production, it is crucial to validate that the equipment, staffing, production methods, capacity, and quality control plan are in place for each product line.

Global Wits Consultancy Services offers on-site quality support to prevent and reduce the potential cost of poor quality (COPQ) and risk, ensuring a smooth transition from product development to mass production.

Global Wits Consultancy Services’s Quality Solutions:

Engineering Build (EB) and Quality Build (QB) Audit

First Article Inspection (FAI)

APQP/PPAP Audit

Manufacturing Process Audit

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Factory not ready for mass production

Shipment delays due to critical failure, poor quality, and resource constraints

An exponential increase in defective products

Product recall

High Cost of Poor Quality

An exponential increase in the cost of change after mass production commences

Production & Delivery

Production planning ensures that the supplier has sufficient raw materials, components, and staff and that other outsourced processes meet the specified schedule.

Global Wits Consultancy Services offers assistance in timely supplier communication, onsite visits, and daily or weekly monitoring reports. This minimizes the risks of delays from ineffective procurement planning, staff shortages, or sub-supplier mismanagement.

Global Wits Consultancy Services’s Quality Solutions:

Order Expediting

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Production delay due to poor material procurement planning

Production delay due to inadequate production staffing

Poor sub-supplier management

Incoming inspection reflects a factory's commitment to quality control from the outset. Understanding how a factory manages its incoming material and its supply chain is a very good indication of its commitment to quality.

Global Wits Consultancy Services quality solutions address issues such as defect acceptance, material substitutions, and component decay due to poor practices or storage conditions.

Global Wits Consultancy Services’s Quality Solutions:

Incoming Inspection

In-Process Inspection

Manufacturing Process Audit

Supplier Risks & Challenges:

The factory does not manage the quality of its supply chain or is poor at supplier management

Suppliers turn a blind eye to defective components during incoming and still use them for production and assembly

Using sub-standard material or components (e.g., lower-quality fabric than required)

Substituting lower-cost alternatives for product components (e.g., cheaper electronic components in a mobile phone)

“Quality fade” where suppliers make small, gradual substitutions in materials and components over time

Bulk material ordered by the supplier degrades over time due to poor storage conditions

Many things can go wrong during mass production due to machine failure, lack of process control, and operator mistakes. While it is normal for defects to occur, these defects must be detected and contained.

Global Wits Consultancy Services offers a range of support to verify control plan adherence, early defect detection, quality improvement, and issue resolution through monitoring, investigations, and CAPA validation.

Global Wits Consultancy Services’s Quality Solutions:

First Article Inspection (FAI)

In-Process Inspection

Manufacturing Process Improvement

Quality/Root Cause Investigation (8D)

CAPA Verification

Order Expediting

End-Of-Line Testing & inspection

Resident Supplier Quality Resourcing

Supplier Risks & Challenges:

Operators are not producing according to the production control plan

Supplier is under pressure to ship goods, turning a blind eye to defective components

Lack of quality staff to enforce quality control

Poor control of re-worked material/product

Mistakes made by temporary, untrained staff/operators

Communication breakdown when the supplier is under pressure

The smallest aesthetic defect on the packaging or missing components can lead to customer returns, while a misplaced label may result in compliance issues. Outgoing Quality Control is the last line of defense before products are properly loaded into containers for shipment.

Global Wits Consultancy Services offers pre-shipment inspections and end-of-line testing to ensure your products meet your quality requirements and reduce the chance of returns or re-work.

Global Wits Consultancy Services’s Quality Solutions:

Manufacturing Process Audit

Poka-Yoke Implementation

Pre-Shipment Inspection

End-Of-Line Testing & inspection

Container Loading Supervision

C-TPAT Audit

Supplier Risks & Challenges:

Products are poorly packaged

Human mistakes and missing components lead to customer returns

Wrong labeling leads to compliance issues and significant re-work

Rough handling of goods during container loading by the factory or outsourced warehouse, leading to damaged product

Poor container loading leads to product damage during transit

Why Global Wits Consultancy Services?

Partnership

Global Wits Consultancy Services genuinely sees your company and your suppliers as partners looking for growth and improvement. We don’t just give pass/fail results. We provide professional recommendations, facilitation, and performance management to achieve the desired results.

Quality Dashboard

Global Wits Consultancy Services’s Quality Dashboard provides a holistic dashboard view of your supplier portfolio including data analytics to better understand and determine the next action required at your supplier.

Experience & Expertise

Global Wits Consultancy Services has overseen successful supplier transformation projects helping companies from the packaging industry achieve their quality goals.

Global Presence

Global Wits Consultancy Services has agile teams of inspectors and auditors a lot of countries ready to meet your quality assurance needs whether it’s a packaging quality inspection or a comprehensive factory audit.